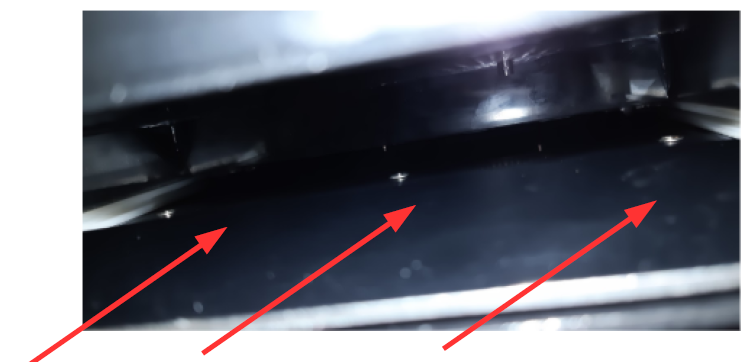

A good practice is to check the microplate receptacle for accumulated debris at least once every six months. This debris can typically be identified as white particles attached to the bottom plastic, which can be observed using a lantern.

If a significant quantity of debris is detected, it’s crucial to address the issue promptly. Accumulated microscopic debris has the potential to interfere with the light microholes over time. Therefore, it’s imperative to take action by cleaning the WMicrotracker receptacle to maintain the integrity and accuracy of your analyses.

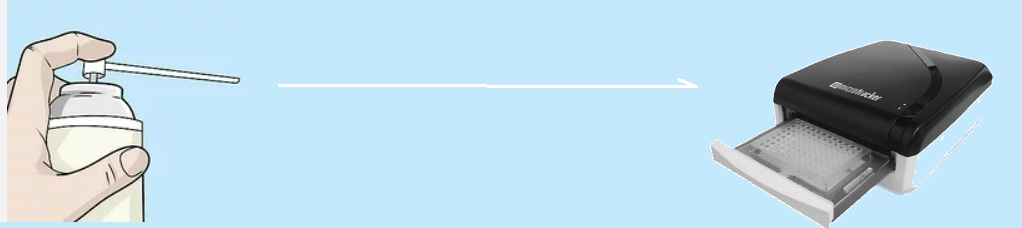

To effectively clean the microplate receptacle, particularly its bottom side, utilize compressed air. It is advisable to use compressed air of a quality similar to that employed for cleaning computer keyboards. It’s crucial to avoid using industrial-grade compressed air, as it may contain contaminants such as dust or humidity, which could potentially exacerbate the issue.

Cleaning procedure:

1) Begin by opening the tray to gain access to the microplate receptacle.

2) Utilize a lantern or similar light source to thoroughly inspect the receptacle for any signs of debris or contamination.

3) Using the compressed air, direct airflow into the bottom zone inside the receptacle, ensuring coverage from the far left to the far right. This process helps dislodge and remove any microscopic particles that may be present.

4) After completing the air-purging process, visually inspect the receptacle using the lantern once more to verify that any debris has been effectively removed. This step ensures that the receptacle is clean and ready for further use, thereby maintaining the integrity of your microplate analysis.